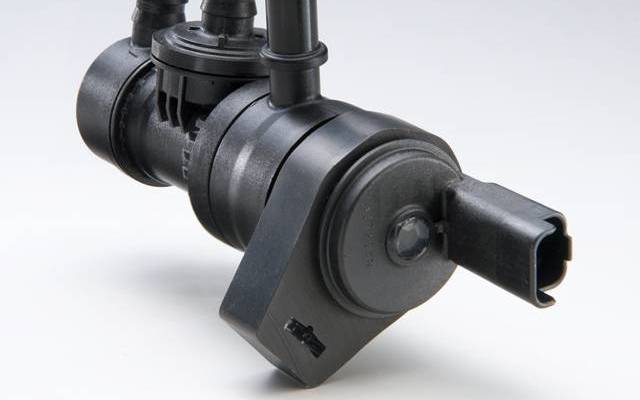

Product photos

Features

- The canister purge valve controls the flow of the gasoline vapor into the engine.

- A smooth start of the flow curve and a high maximum flow.

Originally purge valves were made to avoid emission of gasoline vapor from the gasoline tank. Nowadays this vapor is captured by a carbon canister. Now, the function of the valve is to control the purge flow which discharges the carbon canister content.

The valve is installed in the engine compartment as a solenoid valve that is closed when the engine is turned off. The functionality of the canister purge valve is controlled by the engine control unit according to the current engine load, and the driving signal is based on pulse wide modulation with variation of the duty cycle.

The purge flow is the result of the pressure difference between the intake manifold and the atmosphere side of the carbon canister, when the valve is opened by the duty cycle.

Product specifications

|

Item |

Range |

Unit |

|

Material |

PA6.6 |

|

|

Temperature |

-40 to 140 |

°C |

|

Internal resistance against |

Blow By, E22, E85, M15, M26, fuel ROZ95, fuel ROZ98, RSG E10 |

|

|

Flow rate |

up to 10kg/h |

kg |

|

Pressure difference |

more than 700 hPa is possible |

hPa |

Note: Individual cases may differ according to the seal size. Please consult us before use.